Thread-rolling screws

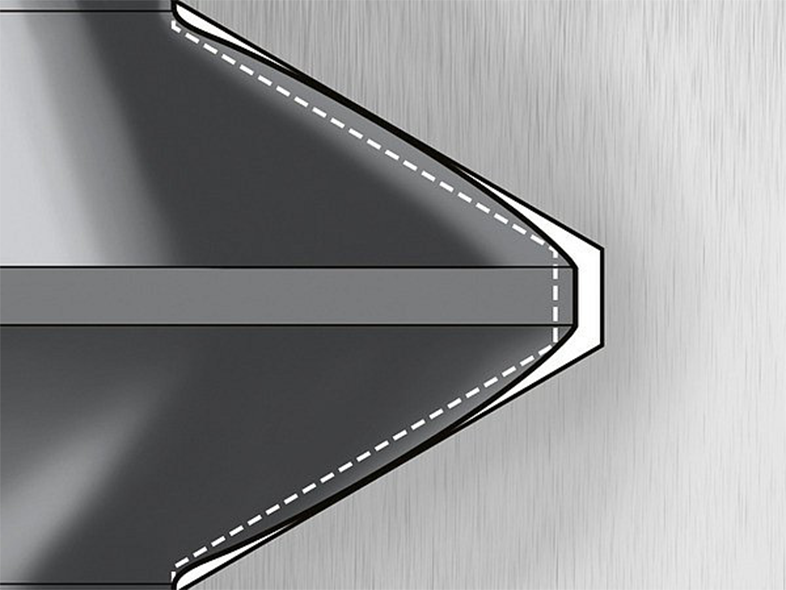

Thread-rolling screws are screws that form their mating thread themselves in a pre-drilled or cast core hole without cutting by means of special thread geometry. Thread-rolling screws therefore act as a positive-locking retainer.

These screws are used in through-holes and very often in cast core holes (aluminium or die-cast zinc).

DIN 7500

DIN 7500 is the oldest and most widely used design and defines the thread and the technical delivery conditions. However, screws such as Taptite, Duo-Taptite and Taptite 2000 are also currently very common on the market.

Features

| The requirements for the evaluation of the mechanical and functional properties of a thread-rolling screw include: | |

|---|---|

Surface hardness Edge hardness (E.H.) | DIN 7500 + DIN 267-30 for the FKL 10.9 (ISO 20898-1) |

| Core hardness | DIN 7500 + DIN 267-30 for the FKL 10.9 (ISO 20898-1) |

| Minimum fracture torque | DIN 7500 + DIN 267-30 for the FKL 10.9 (ISO 20898-1) |

| Rolling torque | DIN 7500 + DIN 267-30 for the FKL 10.9 (ISO 20898-1) |

GEFU® SCREWS with TAPTITE 2000® thread are designed so that the advantages of the previous TAPTITE screws are combined with a new thread shape - a thread with a radius profile.

The result is a thread-rolling screw that has exceptional mechanical, connection and ergonomic characteristics which are not surpassed by any other technology.

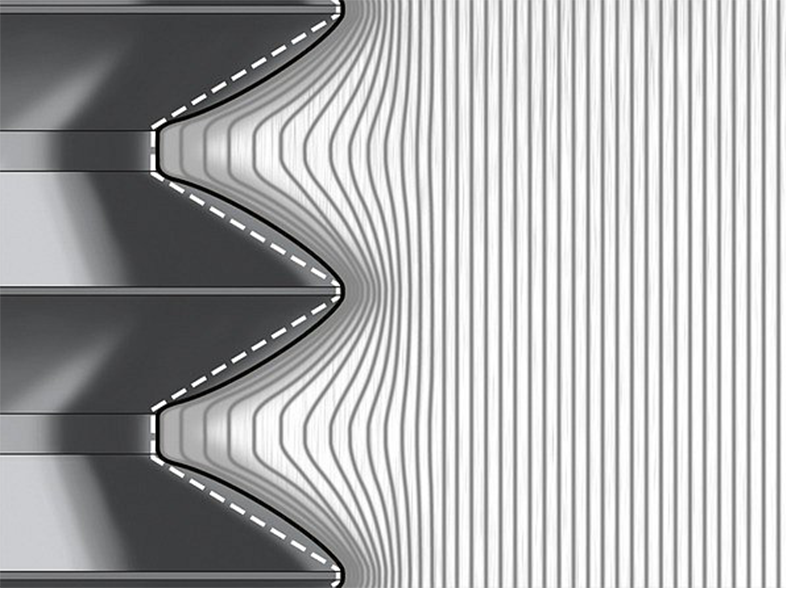

This radius profile facilitates the flowing of the nut material towards the screw thread core.

The TAPTITE 2000® thread reduces the tapping torque by up to 50 percent in comparison with conventional thread-rolling screws as per DIN 7500.

Furthermore, the use of GEFU® TAPTITE 2000® increases the reliability of the screw fitting process and generates higher pretensioning forces.

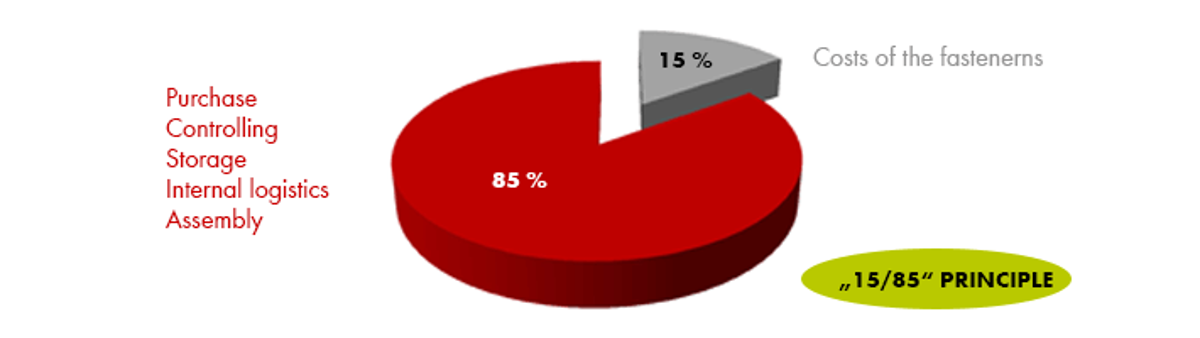

THE "15/85" PRINCIPLE

Using thread-rolling screws reduces incidental costs by up to approx. 85% for thread-cutting, controls, tools, etc. Approx. 15% remains for the fastener itself, i.e. the cost of the screw.

Thread

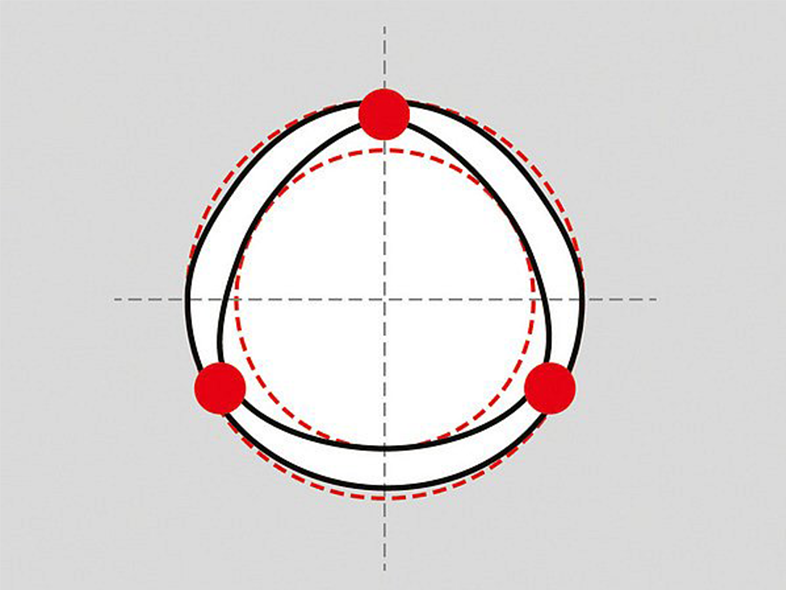

The thread of thread-rolling screws is designed so that the shaped inner thread can take a screw with metric ISO threads (standard thread) with a tolerance of 6 h. The shape and the arrangement of the rolling area of the thread are determined according to purpose.

GEFU®-SCREWS with TAPTITE 2000® thread in our Shop

Advantages of thread-rolling screws

- Identical flank contact surface

- Improves insertion torque/over-turning torque ratio

- Improves the torque to pretensioning force ratio