Connection technology for lightweight wood construction

The solution for the caravan industry

The use of lightweight materials has increased, especially in the caravan and RV industry. Lightweight construction is about reducing the mass of materials and replacing them with efficient, weight-reduced materials. It is all the more important that the fasteners ensure stability and safety under high loads. With the COLDMELT® technology from Würth, we offer you an innovative and quick technique that is also economically viable. There are hardly any limits to the range of applications, because wherever lightweight materials are used, COLDMELT® technology can also be used. COLDMELT® technology is the innovative solution for connection technology in lightweight wood-based materials. The reproducible work results ensure maximum process reliability and are therefore ideally suited for industrial processing for the caravan industry and its suppliers.

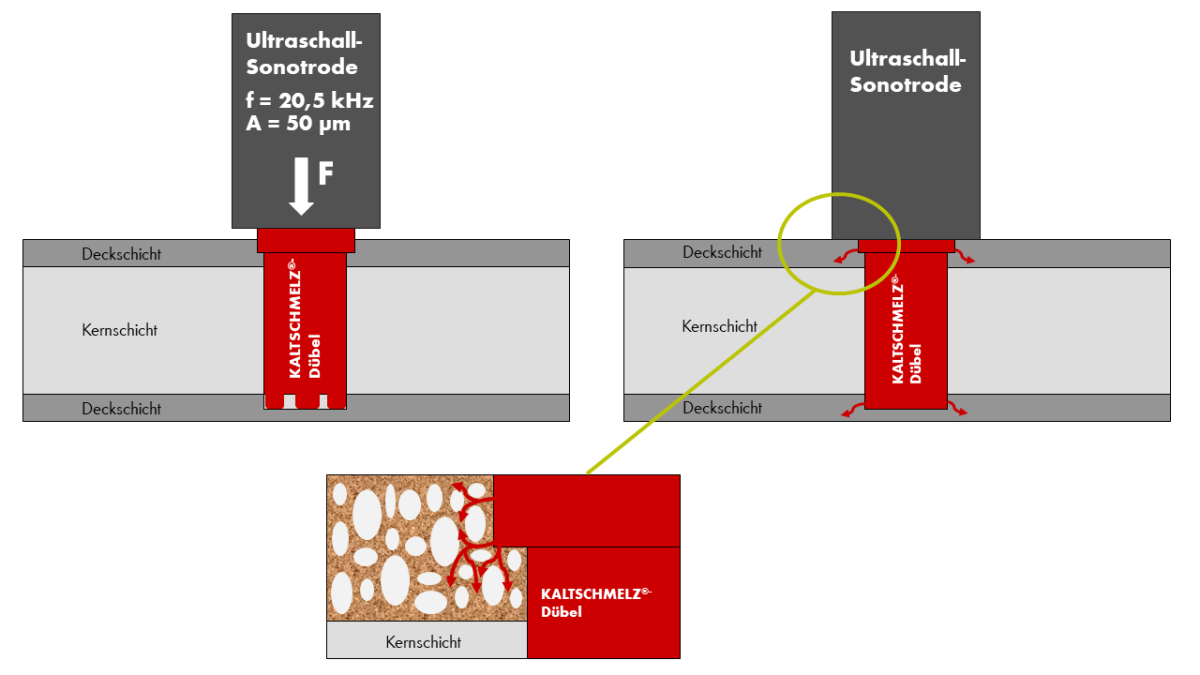

How the COLDMELT® technology works

By applying mechanical vibrations in the ultrasonic range (20,500 Hz), thermoplastic adapters (COLDMELT® dowels) are set in motion. As a result, they melt at the contact points to the cover layer due to the resulting frictional heat and connect positively with the porous structure of the wood material. However, there is only little heat in this process. The development is based on the protected WoodWelding® technology of the WW WoodWelding GmbH from Switzerland. The dowel is mounted in just a few seconds and there is no need to wait for the adhesive to harden, as the joint can be loaded directly.

The newly created attachment points offer two major advantages. On the one hand, it creates a loadable attachment point for e.g. fittings, on the other hand, the thin cover layers of lightweight sandwich materials are firmly connected, so that the lightweight panel is selectively converted to a solid board, but without increasing the weight.

Our procurement and supply expertise.

The Würth Industrie Service GmbH & Co. KG collects and processes the personal data provided in the form in order to process the requested request for you. Please note the mandatory fields in the forms. The legal basis for this processing, the absolutely necessary data, is Art. 6 para. 1 lit. b DSGVO, implementation of a pre-contractual measure. The processing of data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f DSGVO. Thereafter, processing is permissible which is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve our consulting quality and to be able to contact you more easily in case of possible queries. The data collected will only be stored by us for as long as is necessary to process your enquiry and to contact you. They are then deleted.

Supplementary data protection information, in particular regarding your rights to information, correction, deletion, restriction of processing, objection and complaint, can be found in our data protection declaration.