Spare parts supply at Elabo

Short-term spare parts delivery using additive manufacturing

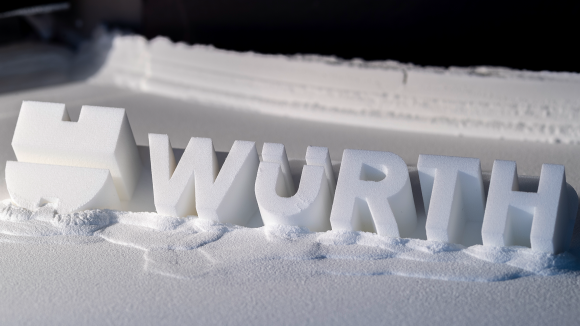

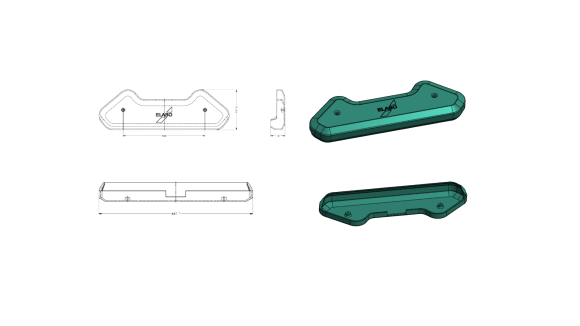

With the use of additive manufacturing technologies, Würth Industrie Service could deliver a cover for a work table to Elabo that they required at short notice.

Initial situation

The procurement of spare parts is rarely an easy undertaking in industrial companies. The part that is needed, is often not available or it is very expensive because of high tool costs. This happened with our customer ELABO GmbH, a provider of testing and inspection systems, worker guidance and technical workplace solutions.

In an innovation project with upcoming filming, a cover of a work table was damaged shortly before filming began. Since this played an important role in the film, a solution had to be found at short notice to replace the cover.

Feasibility analysis and manufacturing

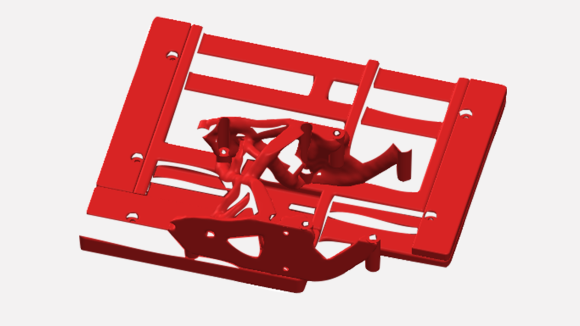

ELABO GmbH turned to Würth Industrie Service, which already acts as a partner in C-Parts supply. After a quick and targeted feasibility analysis, the 3D printing experts of Würth Industrie Service were able to offer a solution to the challenge. A customer-specific spare part was printed in small series without tools and then coated according to customer requirements. This was remedied promptly using additive manufacturing and enabled a successful film work.

Factors of success:

With the help of conventional manufacturing process, it would not have been not possible to manufacture the product in such a short time. Thanks to the company’s 3D printers and cooperation with specialised partner companies, Würth Industrie Service can manufacture spare parts in the shortest time possible. Since the 3D data of the cover was already available, it was possible to start the printing process immediately after the product was selected.

Additional information

Contact

We are here for you!

Please contact us by telephone +49 7931 91 3972 or

via E-Mail under additivemanufacturing@wuerth-industrie.com.

Websites can save or retrieve information in your browser in the form of Cookies. This may be anonymous statistical data, information about you, your settings or devices used, in order to enable a personalised web experience or so that the website works in the way you are expecting it to.

We respect your right to protection of your data. You can therefore decide not to accept certain types of Cookies. For an overview and the settings for the Cookies which we use, please see here. You can change these settings at any time, by invoking our Data protection declaration.

By saving, you confirm that you have understood the settings specified for Cookies and that you agree with them.

The Würth Industrie Service GmbH & Co. KG collects and processes the personal data provided in the form in order to process the requested request for you. Please note the mandatory fields in the forms. The legal basis for this processing, the absolutely necessary data, is Art. 6 para. 1 lit. b DSGVO, implementation of a pre-contractual measure. The processing of data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f DSGVO. Thereafter, processing is permissible which is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve our consulting quality and to be able to contact you more easily in case of possible queries. The data collected will only be stored by us for as long as is necessary to process your enquiry and to contact you. They are then deleted.

Supplementary data protection information, in particular regarding your rights to information, correction, deletion, restriction of processing, objection and complaint, can be found in our data protection declaration.