Smart Workplace – The workplace of the future

Intelligent. Connected. Secure.

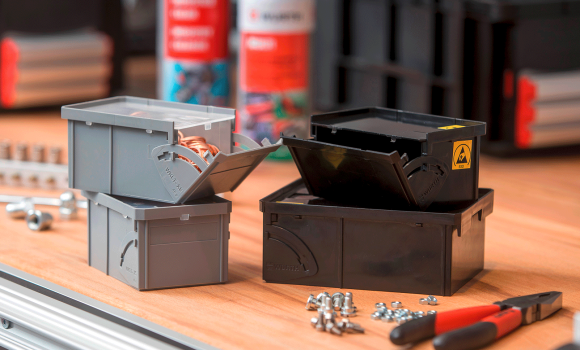

The ever-increasing complexity of logistics and production processes not only increases the demands on the working environment, but also the need to make all work equipment available exactly where it is finally needed: on the shelf, at the storage location or directly at the production line. Thanks to our individual solutions, logistics, work and assembly stations can be integrated directly into the value chain and production supply.

The Smart Workplace combines an ergonomic, supportive workplace that is precisely adapted to the individual needs with intelligent supply solutions.

Maximum supply security. Directly at the workplace.

Complementary solutions from our cooperation partners

At the Smart Workplace humans and machines work hand in hand. In synergy with the digital rack label iDISPLAY, worker assistance systems assure certainty in the work processes and reduce complexity. Autonomous shuttles automatically bring items directly to the workplace, reduce routes and allow more time for value-adding activities.

Advantages of the Smart Workplace

- Maximum availability of your C-Parts directly at the place of usage

- Increase of productivity by elimination of walking distances and reduction of non-value adding activities

- Avoidance of manual error sources

- Ergonomic workstations

- Maximum transparency of inventories and consumptions

- Early identification of demand fluctuations

- Lower capital commitment

- More flexibility within your value chain

- Precise control of the flow of goods

You might find this interesting:

- Catalogue Connected Systems

- Catalogue Innovative Workplace Solutions

- Download centre with our product and system brochures

The Würth Industrie Service GmbH & Co. KG collects and processes the personal data provided in the form in order to process the requested request for you. Please note the mandatory fields in the forms. The legal basis for this processing, the absolutely necessary data, is Art. 6 para. 1 lit. b DSGVO, implementation of a pre-contractual measure. The processing of data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f DSGVO. Thereafter, processing is permissible which is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve our consulting quality and to be able to contact you more easily in case of possible queries. The data collected will only be stored by us for as long as is necessary to process your enquiry and to contact you. They are then deleted.

Supplementary data protection information, in particular regarding your rights to information, correction, deletion, restriction of processing, objection and complaint, can be found in our data protection declaration.