Workplace supply with mobile vending machines

Automated material supply wherever you need it

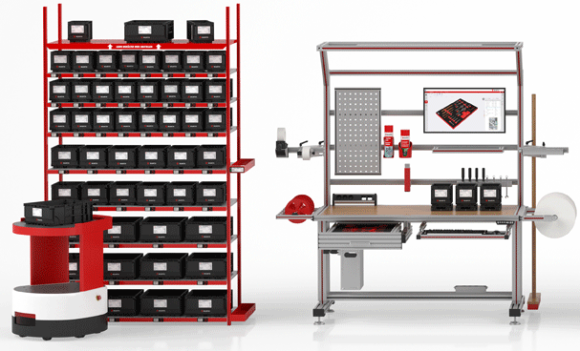

Today's production environment requires flexible, reliable and automated solutions. The ORSY®mat mobil by Würth Industrie Service combines precisely these features – a mobile storage system that can be used wherever it is needed.

In this innovative concept, Würth Industrie Service has combined the tried-and-tested ORSY®mat vending machines with an autonomous mobile robot (AMR) by Gessmann. Thanks to the fast and cost-efficient automation of internal transports, the vending machine can potentially supply materials right to the workstation. The special solution developed by both the partners aims to optimise decentralised material dispensing, offer relief to the employees while also achieving more efficiency, flexibility and security.

Possible use cases

How does the robot know where it is supposed to go?

Thanks to the special sensors that map its surroundings, the robot goes up to workstations and charging stations following the predefined routes, and can also identify and evade any obstacles in its path. It may also be able to use lifts to move across multiple floors - with a control that is absolutely reliable and intuitive.

The mobile GESSbot along with the ORSY®mat, can be summoned from point A to B very easily, together with the digital iDISPLAY and the in-house software solution of Würth Industrie Service. For this, every workstation is equipped with an iDISPLAY that shows the pre-programmed routes that the respective employee can select and request. These are clearly structured and are sorted in the sequence of the incoming orders. Moreover, it is also possible to fulfil urgent requirements by setting priorities in the driving route. The GESSbot Gb350 is also equipped with an integrated display that can communicate with the employees in the immediate surroundings.

The robot handles power supply quite reliably, promptly finding its way to the charging station on its own, docking and charging fully automatically. In future, the production variant of the ORSY®mat will be installed on an autonomous frame inductively powered via the GESSbot. This means that the frames will remain mobile and a single GESSbot will be able to transport multiple vending machines to different places. Absolutely flexible!

Advantages of the AMR technology for production supply at a glance

- Optimisation of time and costs

With mobile and automated supply, you can save valuable time by reducing long routes. This way, your employees can concentrate on their core activities.

- Increased efficiency and flexibility

With the ORSY®mat mobil, items can be made available 24/7 directly at the place of use, making material supply independent of central material dispensing.

- Seamless integration into the existing solutions

The AMR technology is ideal for combining with our other production supply solutions to create a comprehensive and automated supply solution.

- Complete transparency

The ORSY®mat vending machines offer complete transparency across all transactions, withdrawals and orders. This results in potential reduction in consumption.

- Process cost savings

Customers benefit from maximum saving in their process costs due to takeover of demand assessment, purchase requisition, reordering, delivery of goods as well as an optional on-site system filling.

You might find this interesting:

You might find this interesting:

- Press release - The mobile ORSY®mat

- Brochure - CPS®RFID

- Brochure – Connected systems

- Download centre with our

product and system brochures

product and system brochures

The Würth Industrie Service GmbH & Co. KG collects and processes the personal data provided in the form in order to process the requested request for you. Please note the mandatory fields in the forms. The legal basis for this processing, the absolutely necessary data, is Art. 6 para. 1 lit. b DSGVO, implementation of a pre-contractual measure. The processing of data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f DSGVO. Thereafter, processing is permissible which is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve our consulting quality and to be able to contact you more easily in case of possible queries. The data collected will only be stored by us for as long as is necessary to process your enquiry and to contact you. They are then deleted.

Supplementary data protection information, in particular regarding your rights to information, correction, deletion, restriction of processing, objection and complaint, can be found in our data protection declaration.